Learn about Mobile Mechanic Services

Outline and Why Mobile Mechanics Matter

Outline:

– What mobile mechanic services are and how on-site repairs work

– Costs, pricing models, and where savings come from

– Capabilities and limitations of curbside repairs

– How to choose a reliable provider and what to expect

– Trends shaping the future and a practical conclusion for drivers

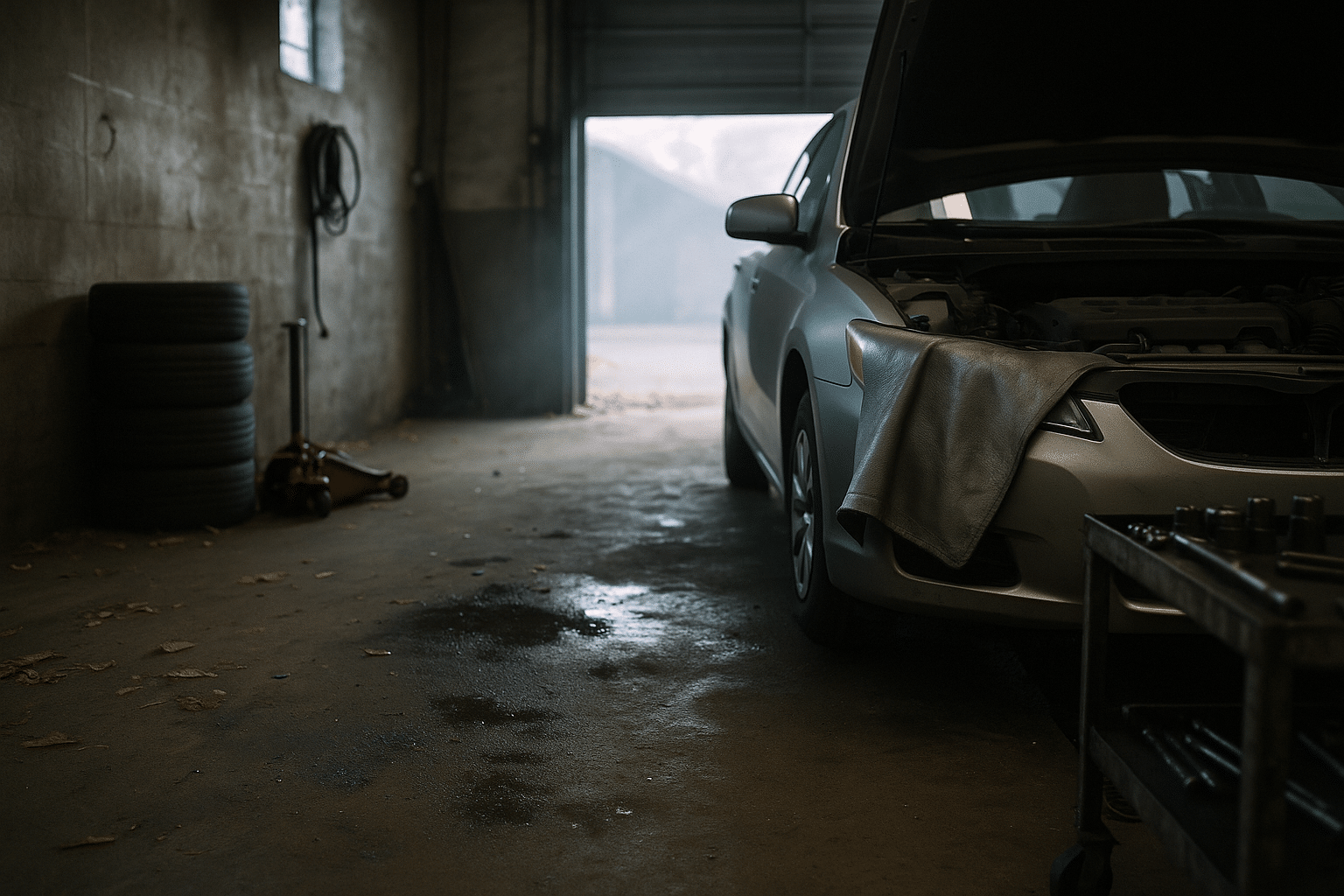

Mobile mechanic services move traditional garage expertise to wherever your vehicle sits: your driveway, a workplace lot, or a parking space outside an apartment. The core idea is simple yet powerful—technicians travel with diagnostic tools, parts, and safety gear to complete maintenance and many common repairs on-site. This model responds to two realities of modern life: drivers value time more than ever, and vehicles have become more reliable yet still need periodic care. By removing the trip to a shop and the wait in a lobby, mobile service often compresses a multihour errand into a scheduled visit that fits the day, not the other way around.

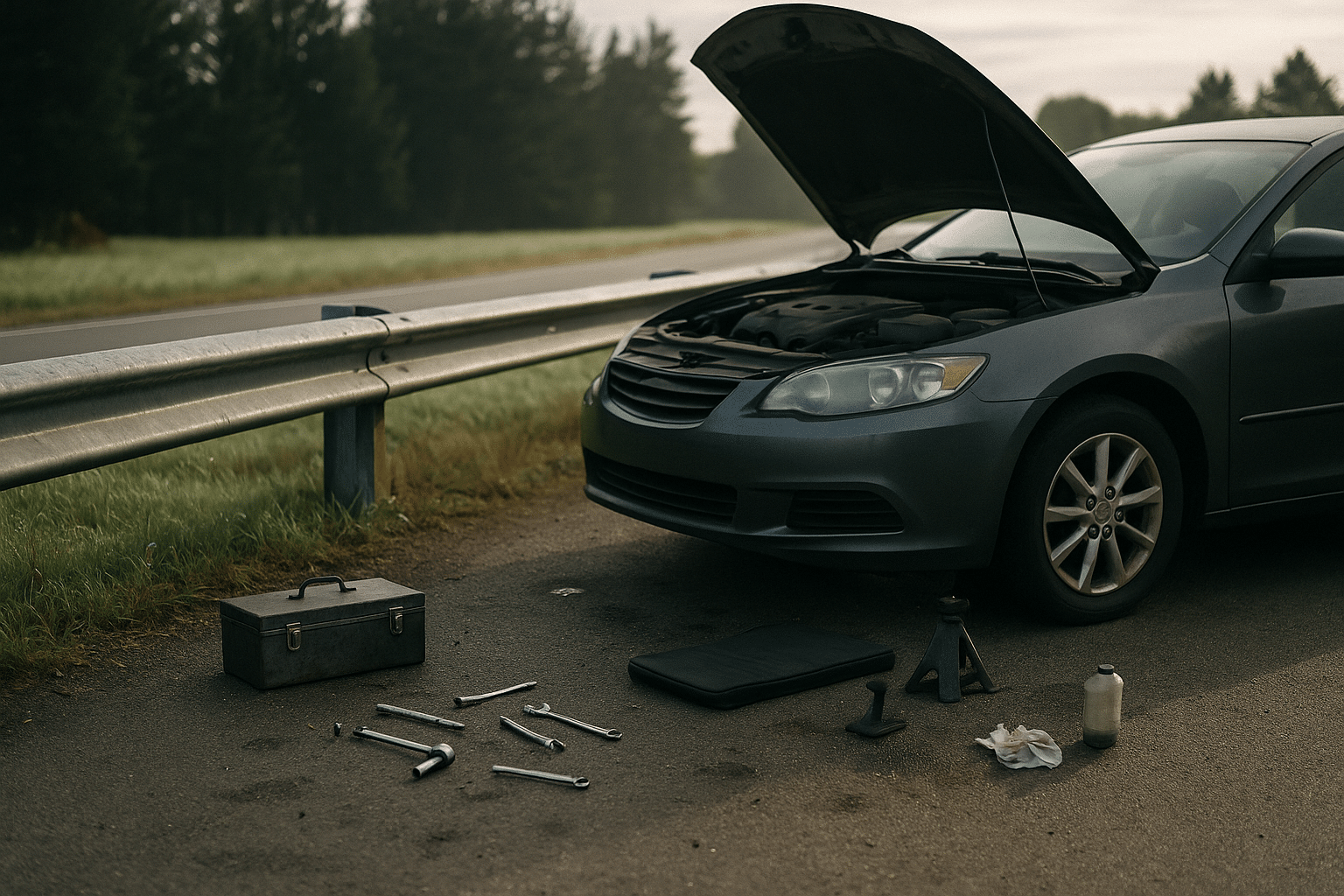

Convenience is only part of the story. On-site repair can reduce towing, which is frequently a hidden cost when a car won’t start. It also helps people in areas with limited access to full-service garages, or those with mobility constraints. Small businesses and fleets gain predictable downtime and fewer logistics headaches. For many issues—weak batteries, brake pad wear, worn belts, sensor faults, oil leaks from an accessible seal—curbside service is practical and efficient. The technician arrives prepared with a plan: verify the complaint, scan for codes when applicable, confirm the root cause, and show you the failed part before replacement.

Because mobile vans avoid the overhead of a large facility, the economics can be attractive. Yet reputable providers still invest in training, insurance, and compliant fluid handling, so quality remains the differentiator. The best experiences are transparent: clear estimates, photos of worn components, and upfront expectations about what can and cannot be completed in a driveway. Think of it as a traveling pit lane—organized, methodical, and designed to get you rolling again with minimal disruption.

Costs, Pricing Models, and Where Savings Come From

Understanding the bill helps you compare mobile visits with a traditional shop. Most services fall into line-item pricing that includes labor, parts, and sometimes a modest mobile or diagnostic fee. Typical labor rates vary by region, but mobile mechanics often price between mid-market shop rates and specialty facilities because they avoid high property overhead. A common pattern looks like this:

– Call-out or inspection fee: a flat amount that may be credited toward the repair

– Diagnostic time: a defined block for scan tool testing and pinpoint checks

– Labor for the fix: a job-based or hourly rate tied to industry time guides

– Parts: sourced locally or brought on the van with standard markup

Consider towing avoidance as an immediate savings. A short local tow can range widely, and after-hours or long-distance requests climb quickly. If a no-start is solved at your curb with a battery and terminal service, you’ve eliminated both the tow and the wait for a shop bay to open. Another savings source is time: not missing work or rearranging school pickups has real value, even if it’s not a line on the invoice. For small fleets, one visit that services several vehicles can multiply the benefit by minimizing downtime and coordination costs.

As a rough frame of reference, drivers may see:

– Routine maintenance (oil service, cabin/engine filters): predictable, often a fixed price

– Brake pads and rotors: priced per axle with labor included, competitive with mid-tier shops

– Starting/charging issues (battery, alternator, starter): diagnostic plus parts and labor, often resolved in one visit

– Sensor-related faults: scan, confirmation tests, then replace or repair the failed component when access is reasonable

Transparency reduces surprises. Ask whether the inspection fee rolls into the repair if you proceed, how warranties are handled, and whether labor rates differ for complex jobs. Clarify parts sourcing—some technicians can install customer-supplied components, while others require parts they provide to maintain quality control and warranty coverage. Finally, confirm any travel surcharges for rural locations or after-hours requests. With these details in hand, you can compare offers on equal footing and choose the option that aligns with your budget and schedule.

Capabilities, Tools, and Job Types: What Can Be Done Curbside

Mobile units today are rolling workshops. A well-equipped van carries a professional scan tool, a multimeter, torque wrenches, impact tools, jack stands, fluid exchange equipment, and safe waste containment. This toolset supports a wide range of maintenance and repair tasks, especially those accessible from above the engine bay or with the vehicle on stands. For many households, that covers the issues most likely to interrupt daily life. Examples include:

– Oil and filter changes, brake pad and rotor replacement, and belt/hoses

– Battery testing and replacement, starter and alternator service

– Ignition coils, spark plugs, and common sensors with reasonable access

– Cooling system work such as thermostat swaps and hose leaks

– Minor oil leaks from gaskets reachable without engine removal

There are practical limits. Some procedures require a lift, alignment rack, or specialized press that would be unsafe or inefficient at the curb. Examples include major suspension overhauls, transmission rebuilds, engine internals, precise alignments, and certain air-conditioning operations that demand large recovery machines. Complex rusted fasteners or seized components can also turn a mobile job into a shop referral if extraction would exceed time, safety, or noise constraints for a residential area. A professional will explain these boundaries upfront, not after hours of trial and error.

Safety and environmental stewardship are nonnegotiable. Expect wheel chocks, jack stands on solid surfaces, drip trays under fluid points, and sealed containers for used oil and coolant. Good practice includes photographing the work setup, confirming torque values against specifications, and double-checking fluid levels before the test drive. Noise control matters in neighborhoods; short bursts from impact tools are normal, but thoughtful techs minimize disturbance. Documentation ties it all together: the invoice should list parts, labor, and notes about diagnostics so you understand what was done and why.

In short, think of mobile service as highly capable for everyday needs and mid-level repairs, with clear handoffs to a shop for heavy, lift-dependent, or precision equipment tasks. This clarity is a strength—not a drawback—because it ensures your car gets the right fix in the right place, the first time.

How to Choose a Reliable Provider and What to Expect on the Day

Picking the right mobile mechanic is part research, part conversation. Start by looking for experience, insurance, and recognizable industry training; while acronyms vary, you want evidence of formal education and ongoing learning. Browse recent customer feedback across multiple platforms and read the full comments, not just the star count, to see how the technician communicates about setbacks, parts sourcing, and follow-up. A reputable provider welcomes questions and sets expectations clearly.

Use this quick checklist when vetting:

– Ask for a written or digital estimate that breaks out labor, parts, fees, and taxes

– Confirm warranty terms for both parts and labor, and where warranty work is performed

– Request proof of liability coverage and any local permits for mobile operations

– Clarify whether driveway, street, or garage access is needed and if there are HOA rules

– Verify payment methods, deposit requirements for special-order parts, and cancellation windows

Before appointment day, prepare the site. Clear at least a car’s length of space around the vehicle, move children’s toys and pets indoors, and provide a flat, stable surface if possible. If the car is in a public lot, check that maintenance is permitted; some properties restrict fluid services. Expect an arrival window to accommodate traffic and parts pickup. Most visits begin with a brief interview about symptoms, then a verification step and scan when applicable. Good technicians document findings, show you worn components, and explain the proposed repair in plain language before proceeding.

After the job, you should receive a detailed invoice with:

– Parts numbers and quantities

– Labor times and notes on inspected items (brakes, fluids, belts, tires)

– Photos of the old parts or measurements such as brake rotor thickness

– Recommendations prioritized by safety, reliability, and budget

Communication is the thread that keeps everything smooth. If a bolt snaps due to corrosion, or an extra seal is needed, a professional pauses, informs you, and revises the estimate before continuing. That transparency builds trust and ensures there are no surprises when the toolbox latches shut and the van pulls away.

Trends, Technology, and a Practical Conclusion for Drivers

Mobile repair is evolving alongside modern vehicles. Remote pre-diagnostics are increasingly common: you describe symptoms, share a brief video or sound recording, and the technician arrives with targeted parts instead of a generic kit. Connected vehicles and inexpensive readers make it easier to gather fault data before the van departs. This translates to fewer repeat visits and shorter repair times. Electric and hybrid models are also reshaping services; while high-voltage systems demand specialized training and safety gear, many routine tasks—tire rotations, brake service, cabin filters, 12‑volt batteries, wiper motors—remain well within mobile scope. Thermal management for electrified powertrains sits on the boundary: some coolant loop work is curb-friendly, while others require shop equipment for precise bleeding and testing.

Sustainability is a growing focus. Responsible providers use spill kits, recycle oil and coolant, and prefer low-odor cleaners. Paperless invoices and digital inspections reduce waste and make it easy to track maintenance history. Fleet managers often combine mobile service with condition-based schedules, using data to decide when to rotate tires or replace brake components. For households, app-based booking and live location updates remove uncertainty without forcing you into a rigid timeline.

Looking ahead, expect more specialized vans—some geared toward diagnostics, others configured for tires, brakes, or climate systems. Tooling is getting lighter and more powerful, bringing shop-grade capability to the curb without sacrificing safety. Training will keep pace, with technicians pursuing advanced coursework on driver-assistance systems, network communication faults, and battery management for electrified vehicles. That expertise, combined with thoughtful customer service, makes mobile repair one of the top options for everyday automotive care.

Conclusion: If you value time, clear communication, and repairs that fit your schedule, mobile mechanic services are well worth a look. Start with a transparent quote, verify credentials and insurance, and prepare a safe work area. Use the guidance in this article to match job type to service format, and you’ll minimize downtime while keeping your vehicle reliable. With the right provider, the only thing you’ll need to do is hand over the keys and get back to your day.