Roofing Replacement: A Homeowner’s Guide to Costs, Materials, and Timeline

Planning Your Roof Replacement: Scope, Timing, and the Outline

A new roof protects the structure, keeps energy bills predictable, and preserves curb appeal, yet the decision to replace often feels like stepping onto a high ridge in gusty wind. The stakes are real: a tired roof can invite leaks, mold, and structural deterioration, while a well-executed replacement safeguards your investment for decades. Before you compare materials or call crews, set the foundation with a clear plan—what needs to be replaced, when, and why—so the project runs smoothly from the first shingle lifted to the final inspection.

Outline of this guide at a glance:

– Materials and systems: what they’re made of, how long they last, and which climates they suit

– Cost breakdown and budgeting: what you’re really paying for and how to control it

– Timeline and process: what happens each day and how weather plays a role

– Hiring, permits, and warranties: documents to secure and details to check

– Conclusion and next steps: turning knowledge into a confident, timely decision

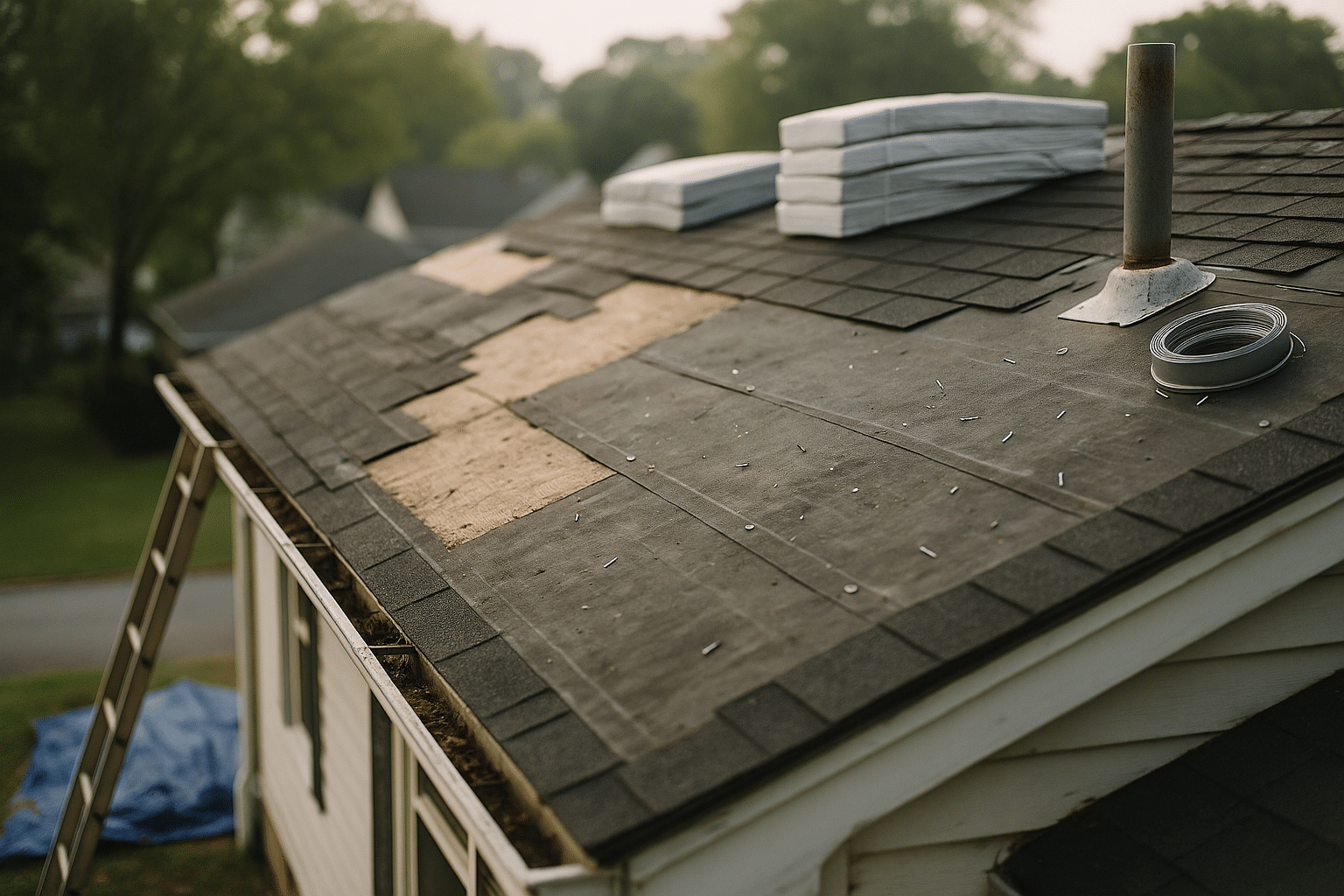

Start by assessing scope. Ask whether you need a full tear-off or if a code-compliant overlay is feasible. A tear-off removes old materials, exposes hidden issues, and typically yields a longer-lasting result. Signs that a full replacement is prudent include curling or missing shingles, granule loss, widespread blistering, chronic leaks, sagging decking, and daylight visible in the attic. In cold regions, recurring ice dams and stained ceilings suggest failed underlayment or poor ventilation. In hot climates, heat-baked shingles and brittle seals hint that the roof has aged out. If you have a flat or low-slope roof, ponding water and seam failures are strong indicators the membrane needs renewal.

Timing matters more than most homeowners expect. Many crews book out weeks during peak seasons. In temperate zones, late spring and early fall offer steady temperatures that help sealants cure; in colder markets, aim to dry-in before recurring freezes. Plan around regional storm cycles to reduce delays. Practical prep reduces friction:

– Clear driveway and pathways for material delivery and dumpsters

– Protect attic contents with tarps to catch dust and stray debris

– Trim overhanging branches that complicate access and safety

– Reserve contingency days for weather and inspections

Finally, align goals with the budget and design. Are you prioritizing longevity, wind resistance, environmental performance, or upfront affordability? Discuss ventilation upgrades, ice and water barriers, and flashing details early; these unsung components often separate a roof that survives typical seasons from one that weathers surprises. With a plan and outline in hand, you’re ready to choose a roof system that fits your home and climate without guesswork.

Materials and Systems: Comparing Roof Types and Components

Materials shape performance, price, and appearance. The most common steep-slope choice is asphalt shingles, valued for approachable cost and wide style options. Quality levels vary, but typical lifespans range from about 15 to 30 years, depending on climate, ventilation, and installation quality. Metal roofing—steel or aluminum in panels or shingles—often runs 40 to 70 years with appropriate coatings and fasteners, shedding snow efficiently and reflecting solar heat in sunny regions. Clay and concrete tiles can last 50 to 100 years when installed over proper underlayment, though they add weight that demands strong framing. Wood shingles or shakes provide a classic look, generally 20 to 40 years with diligent maintenance in the right climates. Synthetic composites emulate slate or shake with a lighter load and lifespans commonly noted around 30 to 50 years, offering impact resistance and consistent manufacturing.

For low-slope or flat roofs, single-ply membranes like EPDM, TPO, and PVC dominate. EPDM (a rubber membrane) is known for flexibility and UV resistance. TPO and PVC offer heat-welded seams and reflective surfaces that can lower heat gain. Lifespans vary but commonly fall between 20 and 30 years with proper installation, drainage, and maintenance. Whichever system you choose, remember that roof assemblies are layered. Underlayments—traditional felt or modern synthetics—add water resistance. Self-adhered ice and water barriers guard eaves, valleys, and penetrations against wind-driven rain and ice dams. Ventilation (ridge vents, soffit vents, or mechanical solutions) helps manage attic temperature and humidity, protecting decking and shingles from premature aging.

Match material to climate and architecture:

– Coastal zones: corrosion-resistant metals, robust fasteners, and sealed seams help withstand salt and wind

– Snow country: metal or properly rated shingles with ice barriers and adequate ventilation reduce ice dam risk

– High heat: reflective surfaces, light colors, and elevated air flow mitigate thermal stress

– Historic or design-driven homes: tile, slate, or composites maintain character while balancing weight

Fire and impact ratings matter. Many steep-slope systems can achieve a Class A fire rating when combined with the correct underlayment and deck assembly. In hail regions, impact-rated shingles or metal panels can mitigate damage and, in some markets, may influence insurance considerations. Consider acoustics and energy, too: metal on solid decking with proper underlayment is quieter than its reputation; lighter colors and reflective coatings can reduce cooling loads. Finally, think about recyclability and disposal. Metal is widely recyclable; asphalt shingles are increasingly repurposed in paving; tile can sometimes be salvaged. A roof is not just an outer shell—it’s a coordinated system where details like flashing, fasteners, and ventilation do heavy lifting.

Cost Breakdown, Budgeting, and Insurance Basics

Costs vary by region, roof size, pitch, material, and market conditions, but a clear framework keeps surprises to a minimum. On many projects, labor represents 40 to 60 percent of the total, with materials comprising the balance. Tear-off and disposal typically add $1 to $3 per square foot, depending on layers removed and landfill fees. A straightforward single-story asphalt shingle replacement might total several thousand to the low tens of thousands of dollars, while metal and tile often run higher per square foot due to material cost and installation complexity. Steeper pitches, intricate valleys, skylights, and multiple penetrations increase labor hours and accessory materials, pushing totals upward. In dense markets or during storm-driven demand surges, bids can rise with limited crew availability and extended lead times.

To budget effectively, break the job into components:

– Tear-off and disposal: layers, weight, and distance to transfer stations

– Deck repairs: replacing rotten or delaminated sheathing

– Underlayments and ice barriers: coverage zones and thickness choices

– Primary roof material: shingle class, metal gauge, tile type, or membrane thickness

– Flashing and ventilation: drip edge, step flashing, ridge vents, and soffit vents

– Safety, staging, and cleanup: fall protection, dumpsters, and magnetic nail sweeps

Set aside a 10 to 15 percent contingency for hidden issues such as soft decking, damaged fascia, or unflashed chimneys discovered during tear-off. Many owners ask about return on investment. While exact figures fluctuate by market, midrange asphalt shingle replacements commonly recoup a significant portion of project cost at resale, and well-documented upgrades can speed buyer confidence. Energy savings from reflective surfaces or improved ventilation add long-term value, though they rarely offset the entire project cost by themselves. For financing, consider home equity lines, personal loans, or staged payments; compare interest rates, fees, and repayment schedules. Some contractors offer financing; evaluate total cost, not just monthly payments.

Insurance is another puzzle piece. If damage stems from a covered peril such as wind or hail, a claim may apply. Understand whether your policy pays actual cash value (depreciated) or replacement cost value (full replacement after deductible and conditions). Review exclusions for wear and tear, cosmetic damage, and code upgrades; some policies offer endorsements for ordinance and law coverage that can help when current code requires additional materials or ventilation. Maintain detailed documentation—photos, inspection notes, and invoices—with clear line items for materials, labor, and permits. Accurate records support both claims and resale narratives.

Timeline, Process, and What to Expect On-Site

Roofing follows a rhythm, and knowing the beat helps you plan family schedules and protect the home during the work. After an initial inspection and measurement, expect a written proposal detailing scope, materials, ventilation strategy, flashing, and cleanup. Permits can take a few days to a couple of weeks, depending on the jurisdiction and whether structural review is needed for heavier materials. Material delivery typically arrives shortly before the start date; crews may place bundles strategically to avoid overloading a single truss bay. With weather windows aligned, the crew sets a start time—often early morning—to maximize daylight and beat afternoon showers.

A typical steep-slope timeline looks like this:

– Day 1: Protect landscaping and siding, set safety lines, strip old roofing, inspect decking, and replace damaged sheathing as needed. Install drip edge and begin ice and water barrier at eaves and valleys. Dry-in with underlayment before the end of the day, especially if weather threatens.

– Day 2: Install primary roofing (shingles, metal panels, or tiles), complete flashings at walls, chimneys, and penetrations, and set ridge vents. On simple roofs, crews may finish the field and ridges in one long day.

– Day 3: Wrap up details, paint exposed metal where specified, conduct magnetic nail sweeps, and arrange inspections. Larger, steeper, or complex roofs can extend to 4–5 days; metal and tile systems often require additional time for layout and finishing.

Weather is the wildcard. Light wind generally is manageable, but steady rain pauses shingle installation because adhesives and underlayments need dry contact. Gusts complicate tear-offs; hot days require more breaks; cold snaps slow sealant activation. Your role as the homeowner is straightforward:

– Clear driveways and keep vehicles off-site during working hours

– Secure fragile items on walls and shelves due to vibration

– Cover attic possessions with drop cloths to catch dust

– Keep children and pets indoors or supervised away from work zones

Noise and foot traffic are the norm—think hammering, compressors, and the occasional thud as debris hits the dumpster. Good crews communicate daily progress and any discoveries, such as unexpected deck damage or unflashed sidewalls. Inspections may occur mid-project (to verify underlayment or nailing) and at completion. After the final walk-through, expect a tidy site, sealed penetrations, verified ventilation, and a packet with warranty registrations and care recommendations. A well-managed process feels like a choreographed build: steady, predictable, and secure against the forecast.

Contracts, Permits, Warranties, and Your Next Steps

Strong paperwork is the quiet hero of a durable roof. Start with contractor vetting: confirm a current license where required, general liability and workers’ compensation coverage, and a physical business address. Ask for recent, local references and photos of similar projects. A thorough proposal should list materials by type and thickness, underlayment and ice barrier coverage, flashing method at chimneys and sidewalls, ventilation calculations, and disposal plans. Clarify who secures permits and schedules inspections. Request a detailed change-order process to document any scope adjustments and costs before work proceeds. To protect your investment, collect lien waivers upon progress payments so suppliers and subcontractors confirm they’ve been paid.

Permits ensure your roof meets structural and fire codes and that ventilation aligns with current standards. Heavier materials like tile may require verification that framing can support the load. In snow regions, codes often dictate ice barrier extents; in high-wind zones, nailing patterns and fastener types follow specific requirements. Inspections are not hurdles—they’re guardrails that keep the project compliant and durable.

Warranties come in two parts. Material warranties cover defects in the roofing product, often on a prorated schedule tied to documented installation and ventilation requirements. Workmanship warranties are issued by the contractor and typically range from a few years to a decade or more, depending on company policy. Look for:

– Clear term lengths and any proration schedules

– Transferability terms if you plan to sell

– Wind and impact limitations, and required maintenance steps

– Registration steps and deadlines to activate coverage

As you move from planning to action, summarize your playbook. Set your goals (longevity, weather resistance, style), pick a system aligned with climate and structure, and define a realistic budget with a contingency. Schedule work for a favorable season, and insist on written scope, permits, and warranty registrations. When the dumpster rolls away and the ridge vents whisper in a steady breeze, you’ll have more than new shingles or panels—you’ll have a weather-ready, code-compliant shield over everything you value. That peace of mind arrives not by chance but by process: careful planning, informed choices, and a paper trail that stands up to time and storms.